01. Primary Power System

The watch’s barrel is the power source of the entire watch. The cassette generally consists of four parts, namely, cassette hub, cassette cover, cassette shaft and hairspring. The prime mover system transfers energy through the meshing of the gear teeth of the watch box with the gear shaft of the second wheel.

The spring is an elastic spring which, when coiled, produces a torque that powers the watch.

The size of the winding torque should meet the requirements of the pendulum, nowadays the watch mostly adopts S-shape winding, its torque fall is small, so that the difference between the pendulum when it is fully wound and the pendulum after 24H is small, and the number of the winding working circle should meet the requirements of the watch’s continuation of timekeeping.

02. DrivelineSystems

Current movements are basically divided into two-wheeled or two-wheeled layouts. The centered second wheel is used to carry the display system and is friction-fit to the split wheel, as in ETA 6498° The off-center second wheel exists only to transmit the power from the prime mover and has no direct connection with the display system, as in ETA 2824, ETA 2892. The third wheel connects to the second wheel to receive the power and at the same time alters the ratio of the wheel system gears, as well as the direction of rotation of the wheel system, and serves as a transition. The third wheel is also known as the second wheel.

The fourth wheel, also known as the second wheel, is connected to the escapement, and its rotation is controlled at a rate of one revolution per minute. The wheel’s axle can be fitted with a second hand (large three-hand ETA 2824, ETA 892 or small three-hand ETA 6498).

03. Escapement

The function of the escapement is to transmit the energy provided by the prime mover system to the balance-spring system at regular intervals to maintain the continuous operation of the system, and to transmit the number of oscillations of the balance-spring system to the indicating device for the purpose of measuring time.

The escapement includes an escapement wheel and an escapement fork. The escapement wheel drives the escapement fork to complete the action of releasing, transmitting and dropping. The “ticking” sound of the mechanical watch also comes from the fact that when the teeth of the escapement wheel buckle the escapement fork, it will make a “ticking” sound, and then with the swing of the balance wheel, the escapement wheel will continue to rotate and then “answer” a sound when the teeth of the escapement wheel buckle the escapement fork. A sound is snapped on the other side of the escapement fork fork jewels (insiders call these two rubies respectively in tile and out tile).

04. Balance-spring system

The balance-spring system, which serves as the reference for timekeeping, consists of the balance wheel component, the balance-spring component and the balance-cock assembly.

The balance wheel and hairspring parts are very recognizable and the balance cock assembly is a little more complicated, consisting of the balance cock, shock absorber assembly, fast and slow hand parts and outer pile ring parts. The balance wheel is driven by the driving force so that the hairspring is compressed and stretched to drive the balance wheel to rotate clockwise or counterclockwise to produce the vibration cycle as a chronograph to measure the time of the benchmark vibration cycle error will have a direct impact on the accuracy of timekeeping.

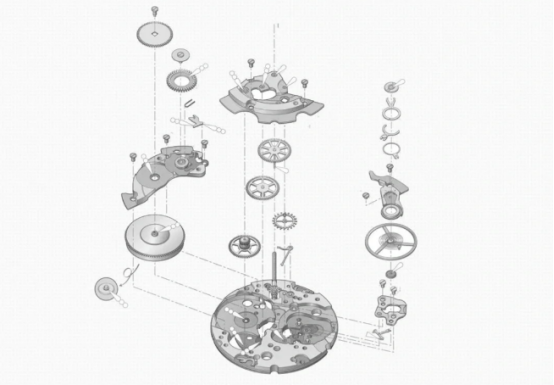

05. Winding Pin System

As the name suggests, when winding the watch, the rotation of the handle is transmitted to the bar axis, prompting the winding coil to tighten and store energy. The transmission of the dial part is to transfer the rotation of the handle to the minute hand and hour hand to realize the role of timing. There are many parts in the winding pin system, as shown in the drawing. When winding, the vertical wheel and the clutch wheel in the state of engagement, when turning the handle, the clutch wheel drives the vertical wheel, the vertical wheel and through the small steel wheel and the large steel wheel to make the bar shaft coil tight clockwork. The pawl prevents the small and large steel wheels from reversing.

When dialing the needle, pull out the head of the handle, the gear in the gear shaft rotation and push the clutch lever, so that the clutch wheel and the vertical wheel disengagement, and dial wheel engagement. At this time, turn the handle to make the dial wheel drive the hour wheel and minute wheel through the cross wheel to achieve the purpose of correcting the hour and minute hands.